ORPMS - Planned Maintenance System

The core of our ERP suite, ORPMS is a full fledged marine planned and predictive maintenance system (PMS). Developed over 25+ years, ORPMS is in use in over 500 vessels worldwide, with the primary user being Anglo-Eastern Ship Management (worldwide).

- Equipment breakdown / downtime is to be reduced

- Revenue lost due to vessel downtime is a concern and is to addressed

- Ensuring maintenance jobs are done as per class or manufacturer recommendation is a priority

- Tracking the usage of spares to ensure replenishments are done on time is vital

- Entire fleet data captured by multiple stakeholders is to be made available on a single platform

- The existing legacy platform (usually Microsoft Excel) does not perform as per your present needs

Main Features

Manage Equipment Structure

Central Job Scheduler

Job Details Management

Automatic Planning

Critical Equipment

Pending Job Alerts

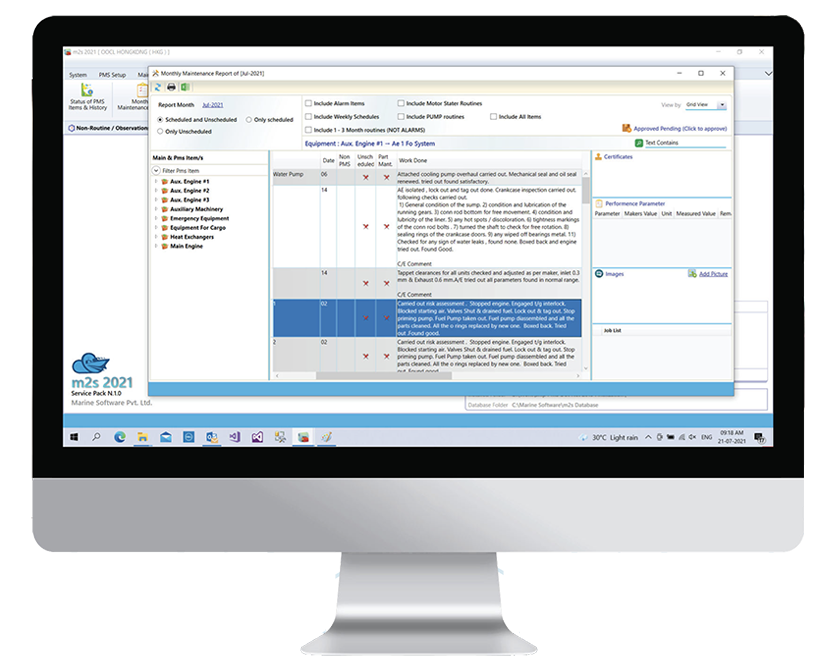

Intuitive Job Planner

Quick and Intuitive Jobs Planner for seamless planning

Cloud Data Management

Access, maintain and monitor all fleet technical data from the office

Data Access Rights

Set data access rights and approval levels according to vessel and office hierarchy

Insights

360° Overview

Auto 0r Manual Data Sync

Error free replication of data between the ships and shore through automatic data synchronisation. Manual synch option for low connectivity areas at sea

Circulating Components

KPIs & Dashboards

m2s allows to create customised dashboards providing users with the customisable data analytics with KPIs provided

Multi Language

SmartData Packets

For Manual Synchronisation to the cloud server, we use the smallest data packets to preserve your satellite internet data

Web Based Office Module

Check your fleet from anywhere via the included Web Based office module in a browser or mobile App

Marine software Planned Maintenance System for Ships – ship PMS

Marine Software’s Marine ERP, often referred to as ORPMS, is a cutting-edge solution designed to revolutionize maintenance practices in the maritime industry. With meticulous planning and systematic scheduling at its core, our system empowers shipowners and operators to proactively manage their vessel’s maintenance needs. By automating routine inspections, repairs, and servicing tasks, this suite ensures that ships remain in peak operating condition. Its intuitive interface, coupled with advanced analytics, not only streamlines maintenance workflows but also assists in making data-driven decisions. With ORPMS and m2s, vessel operators can enhance safety, extend the lifespan of critical assets, optimize maintenance costs, and ensure compliance with stringent maritime regulations. It’s the compass guiding maritime professionals toward more efficient, reliable, and sustainable fleet operations.

Advantages of using our system

Utilizing Marine Software’s m2s onboard ships offers a multitude of advantages. Firstly, it ensures systematic and timely maintenance, reducing the risk of equipment failures and unscheduled downtime, which can be both costly and dangerous at sea. Additionally, ship PMS enhances safety by meticulously tracking and managing safety-critical components, thereby minimizing the chances of accidents. This system also aids in regulatory compliance, helping vessels meet stringent maritime standards effortlessly. Furthermore, it improves overall operational efficiency by optimizing maintenance schedules, reducing costs, and extending the lifespan of onboard equipment. With user-friendly interfaces and advanced data analytics, Marine Software’s ship PMS empowers maritime professionals to make informed decisions, resulting in a more reliable, efficient, and profitable fleet operation.